Describe an Automatic Drill and Explain How It Is Used.com

When several holes are required to be made in one particular place. It is used to hold the drill bit in its place.

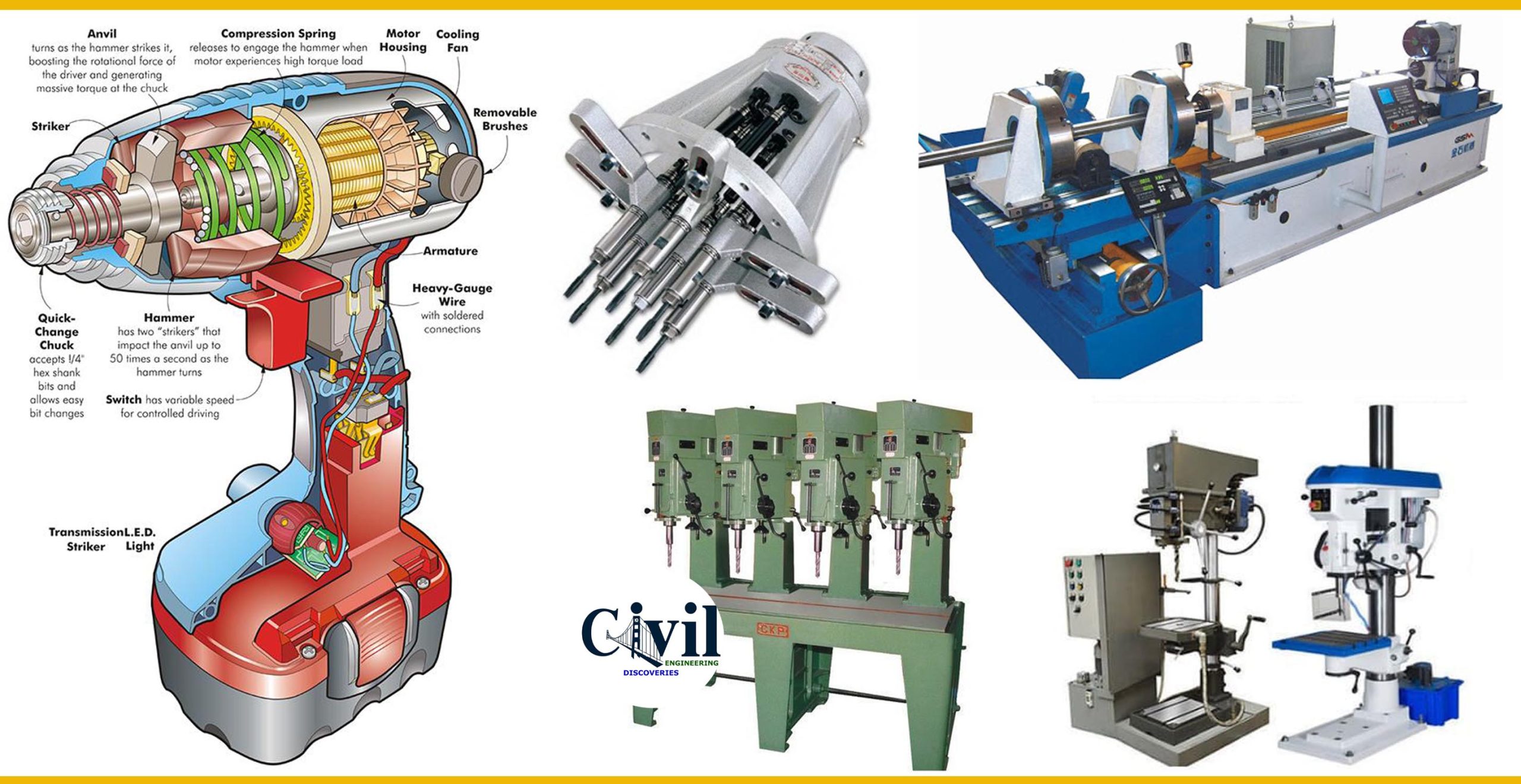

Drilling Machine Definition Parts And Types Engineering Discoveries

Blanks of various size and shape are rigidly clamped on the bed or table or in the vice fitted on that.

. Drill bits are used to drill holes in the workpiece. Explain the reasons for the large difference between the specific energies involved in machining Table 212 and in grinding Table 262. Theres a button near the trigger that tells the drill whether to go forward.

Why is a low-voltage thermostat normally more accurate than a high-voltage thermostat. Drill jigs are used when there is a need for multi-tasking. Such drilling machines are most widely used and over wide range light to heavy work.

Currently twist drills are manufactured by two machining spiral flutes or grooves that run lengthwise around the body of the drill. Because unanticipated thermostat cycles shows system lag and system overshoot causing larger temperature swing. The key is usually stored on the drill top or in the handle.

Dressing-conditioning producing sharp new edges on worn grains on the grinding surface of a wheel. This is the part that rotates and enters the workpiece creating holes. Tool or Drill Bit.

It is a machine which is used to drill the holes on the components or workpiece with the help of drill bits. Drill and practice will aid in efficient learning of higher-order-thinking activities further down in the eLearning course. Explain how to determine the drill size for tapped holes and the importance of using the taps in the correct sequence Determine the drill bit size by reference to a tapping drill chart found on the wall or in a Zeus book.

This is the most common machining process one estimate is that 75 of all metal cutting material removed comes from the drilling operation. It then re-covers the seeds with soil as it passes over the furrow. Truing-the producing of a true circle on a wheel that has become out of round.

Self Feeding Drill Example. Self feed Drill Units provide both a precision motor driven spindle and pneumatic feed in one compact package. Also you could subtract the thread pitch from the tap diameter.

The seed drill consists of a seed hopper plow and harrows and can be pulled by a horse or tractor or pushed manually. This type of drill machine is operated by holding in a hand and the workpiece where the hole is to be drilled is held in a vice. In approaches based on a Behaviourist view of learning such as Audiolingualism drills are considered a key element in the learning.

It also helps in locating the work to the favorable drilling position. In this post well provide a definition of drilling also known as oral drills describe different types of drills and give you practical ideas for the classroom. Loosen the chuck the black circular section on the front of the drill by twisting it counterclockwise to widen the diameter of the jaws that clamp onto the drill bit.

The seed drill was invented by Englishman Jethro Tull in 1701. Multi-Spindle Drilling Machine 7. Drills are used in wide variety of applications in metalworking constructions and woodworking industries.

Drill is a machine tool used for drilling the holes in solid equipment like metal and wood with drill bit or driver bit. Unit 14 Automatic Control Components and Applications. Put the Chosen Bit Into the Drill.

The most renewed example of this class is the hand drill. The Engineering needed for Automatic Drilling is available in one unit with many years of reliable field use with reliable product and spare parts support always available. Portable drilling machine.

The motor is present at the top of the drill head which drives the horizontal axis. The head on a right angle drill is typically much shorter than what youd see in a traditional model too and the grip is usually designed to. Chick is present below the axis.

The drill bit is usually a rotary cutting tool often multi-pointThe bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minuteThis forces the cutting edge against the work-piece cutting off chips swarf from the hole as it is. Low voltage acts faster 2. The three kinds of switching mechanism used in low-voltage.

A seed drill sows seeds at precise intervals into a straight furrow of constant depth. Drilling is a cutting process that uses a drill bit to cut a hole of circular cross-section in solid materials. The most popular type of drill in use today is the twist drill.

Drilling is a technique that consists of the repetition of oral patterns and structures. The 1st tap has a tapered head designed to gradually cut a thread this is protecting the tap from over. A single-point cutting tool like the one used in a lathe machine can remove the material slowly whereas a multi-point cutting tool.

The drill bits are also called as Multi-point cutting tools which can have their rapid impact on the Material Removal Rate MRR ie. In column drills the feed gear box enables automatic and power feed of the rotating drill at different feed rates as desired. The power drill has two other important components.

A right angle drill is basically an electric drill with a head set at a 90-degree angle to the grip. Many household drills use keyless chucks meaning you can hand-tighten them however some drills require the use of a key to tighten the chuck. The table and spindle speed and feed mechanism can be.

Vertical Turret Type Drilling Machine 8. Insert the shank smooth part of the drill bit into the jaws and re-tighten the chuck until the drill bit is secured. It is a small compact drilling machine used principally for drilling operations which can be performed on a regular drill press.

Drilling is a material-removing or cutting process in which the tool uses a drill bit to cut a hole of circular cross-section in solid materials. It was basically formed by twisting a flat piece of tool steel longitudinally for several revolutions then grinding the diameter and point. Therefore it makes sense to use them towards the beginning of your course.

The portable drilling machines are used to drill small holes and are commonly used in the entire workshop. Also increasing the difficulty level of these activities throughout the course helps build a sense of accomplishment in the learner. The drill jig is also used to guide the drill straight through with the help of drill bushings.

Automatic Drilling Machine and Few Others.

What Is Drilling Machine Definition Parts Types Engineering Choice

Drilling Machine Definition Parts And Types Engineering Discoveries

Drilling Machine Definition Types Parts Operation Application Tools

0 Response to "Describe an Automatic Drill and Explain How It Is Used.com"

Post a Comment